Let me tell you something most backyard cooks don’t want to hear:

Temperature control is not the secret to great BBQ.

Air is.

I’ve cooked long enough to know this truth the hard way. I used to stare at thermometers like they were stock market tickers. If the temp dipped, I panicked. If it spiked, I shut vents like I was plugging a leak in a sinking ship.

And every time my smoke turned thick and bitter, I’d blame the wood.

But the problem wasn’t the wood.

It wasn’t the smoker.

It wasn’t the weather.

It was my misunderstanding of the physics of airflow.

Once you understand how air moves through your smoker – how draft works, how combustion really behaves, and what clean smoke actually means – everything clicks.

And when it clicks, your BBQ changes forever.

Let’s break it down.

Why Airflow Is the Foundation of Great BBQ

BBQ is controlled fire. That’s it.

You’re not just cooking meat. You’re managing a living, breathing combustion system.

And combustion depends on three things:

- Fuel

- Heat

- Oxygen

Remove oxygen, and the fire chokes.

Too much oxygen, and it rages.

The sweet spot? That’s where flavor lives.

The physics of airflow determines how oxygen feeds your fire.

And oxygen determines how cleanly your wood burns.

Clean burn = clean smoke.

Dirty burn = bitter meat.

Simple.

Airflow affects:

- Fire stability

- Heat distribution

- Smoke quality

- Fuel efficiency

- Bark formation

- Even moisture retention

If temperature is the symptom, airflow is the cause.

The Science of Combustion: What’s Really Happening in Your Firebox

Let’s step inside the firebox.

When you throw a split of oak into the fire, it doesn’t instantly turn into flames. It goes through stages.

Stage 1: Moisture Evaporation

Even seasoned wood contains water.

First, that water must boil off.

This produces steam – not smoke.

If your fire struggles here, you’ll see thick white billowing clouds. That’s not flavor. That’s wet wood fighting physics.

Stage 2: Pyrolysis

This is where the magic starts.

Pyrolysis is when heat breaks down wood compounds into gases. Those gases ignite and produce flame.

Wood isn’t just “wood.” It contains:

- Cellulose

- Hemicellulose

- Lignin

When lignin breaks down, it releases the compounds responsible for that signature BBQ aroma.

That’s the good stuff.

But here’s the catch:

If there isn’t enough oxygen during this phase, those gases don’t burn completely.

Instead, they condense into soot and creosote.

That’s when smoke turns thick, gray, and bitter.

Complete vs. Incomplete Combustion

This is the heart of the physics of airflow.

Complete combustion happens when:

- Oxygen supply is steady

- Fuel is properly heated

- Gases ignite fully

It produces:

- Clear heat waves

- Light, almost invisible smoke

- Clean aroma

Incomplete combustion happens when:

- Oxygen is restricted

- Fire is smothered

- Wood is overloaded

It produces:

- Thick white or gray smoke

- Acrid smell

- Bitter flavor on meat

If your smoke smells sharp or stings your eyes, that’s incomplete combustion.

Your meat tastes what your fire breathes.

Understanding Draft: The Engine That Moves Air

Now let’s talk draft.

Draft is the invisible force pulling air through your smoker.

It’s not magic.

It’s physics.

Hot air rises. Always. That’s the chimney effect.

When your fire heats the air inside your smoker:

- Hot air rises up the stack.

- That rising air lowers pressure inside the chamber.

- Fresh oxygen gets pulled in through the intake vents.

That movement is draft.

Draft is what keeps your fire alive without you fanning it like a campfire.

The stronger the temperature difference between inside and outside air, the stronger the draft.

That’s why:

- Taller chimneys create stronger pull

- Hotter fires increase airflow speed

- Cold weather can actually improve draft

- Wind can either help or completely wreck airflow

Your smoker is basically a low-tech engine powered by heat differentials.

And once you understand the physics of airflow, you stop fighting your smoker – and start working with it.

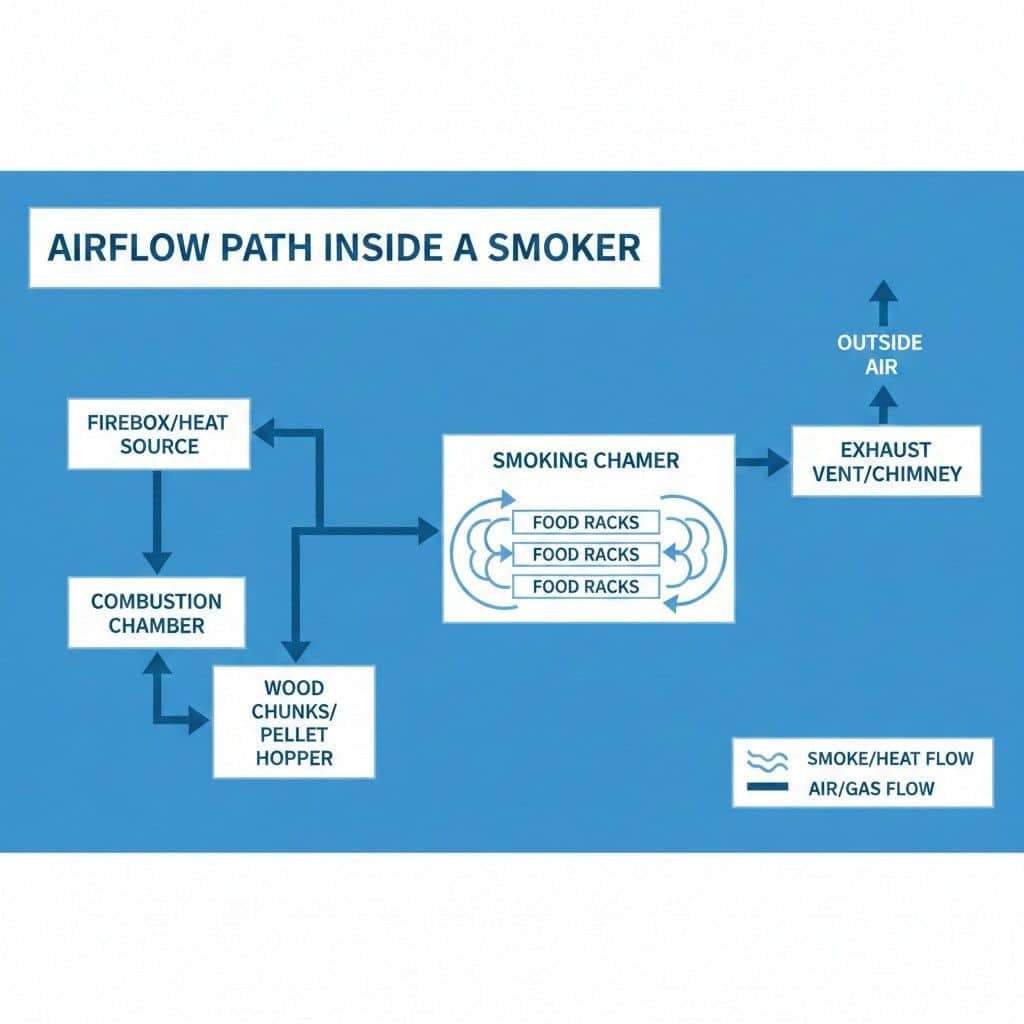

The Airflow Path Inside a Smoker

Think of airflow like a highway.

Air enters.

Feeds the fire.

Moves across the meat.

Exits the stack.

Each stage matters.

Air Velocity vs. Air Volume: Why Speed Matters More Than You Think

Most people think airflow is about how much air enters the smoker.

But here’s the twist: air velocity often matters more than air volume.

You can have plenty of oxygen available, but if it moves too slowly, combustion becomes lazy.

The fire smolders instead of flames. That’s when smoke turns heavy.

Fast-moving air does three important things:

- Feeds oxygen efficiently

- Pulls combustion gases away quickly

- Prevents stale smoke from lingering

Think of it like a river. Slow, stagnant water grows algae. Fast water stays clean.

The same applies inside your smoker.

When draft is strong, smoke doesn’t sit on the meat – it flows across it. That movement prevents over-smoking and keeps flavor balanced.

So don’t just think about “more air.”

Think about how fast the air is traveling.

That’s a subtle but powerful layer of the physics of airflow.

Turbulence vs. Laminar Flow: The Hidden Pattern of Smoke Movement

Here’s something most backyard cooks never consider: not all airflow is smooth.

There are two main types:

- Laminar flow – smooth, even movement

- Turbulent flow – chaotic, swirling movement

Inside many smokers, airflow becomes turbulent as it moves around baffles, meat, and chamber walls.

Turbulence isn’t bad. In fact, controlled turbulence helps distribute heat and smoke evenly.

But excessive turbulence?

That can create hot spots and uneven bark.

If one side of your brisket cooks faster, you’re likely seeing airflow disruption.

Understanding flow patterns inside the cook chamber helps you position meat strategically.

Air doesn’t move in straight lines – it curves, bounces, and rolls.

The more you cook, the more you’ll start reading these invisible patterns.

That’s when you stop guessing.

And start cooking with intention.

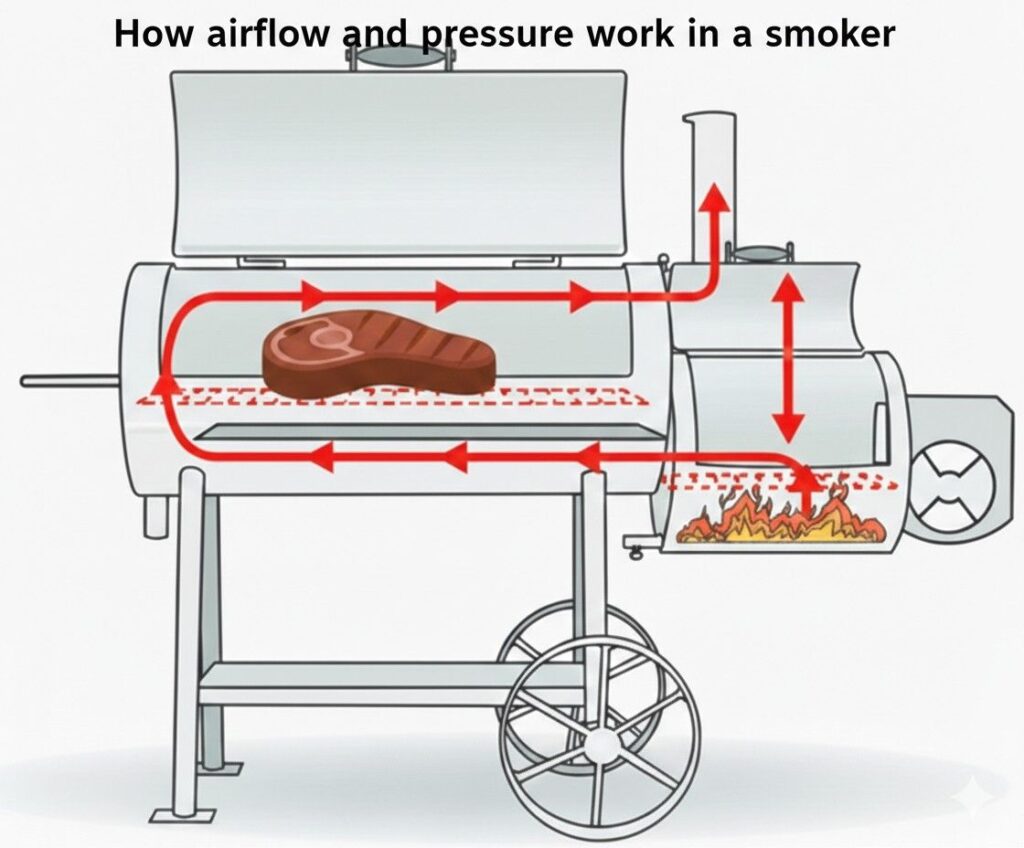

The Role of Pressure Differentials: BBQ Is a Low-Pressure System

Every smoker operates on pressure differentials.

Hot air rising up the stack lowers internal pressure.

That lower pressure pulls fresh oxygen in through the intake.

It’s subtle.

But it’s constant.

If you restrict exhaust too much, you reduce the pressure difference.

Less pressure difference = weaker draft.

Weaker draft = dirtier combustion.

This is why I always say:

Temperature is controlled by intake. Draft is sustained by exhaust.

Your smoker is essentially a low-pressure engine running on heat.

And once you understand that airflow is driven by pressure changes – not just open holes – you stop making random vent adjustments.

You start thinking like an engineer.

That’s the next level of understanding the physics of airflow.

Radiant Heat vs. Convective Heat: Airflow’s Impact on Cooking Style

Not all heat in a smoker is created equal.

There are two main types:

- Radiant heat – direct energy from hot surfaces

- Convective heat – heat carried by moving air

Airflow controls convection.

And convection shapes bark formation, moisture evaporation, and cook time.

Stronger airflow increases evaporative cooling on meat surfaces.

That’s why brisket can stall longer in high airflow environments.

But convection also builds better bark by steadily drying the surface.

Too little airflow?

The surface stays damp. Bark stays soft.

So when you manage airflow, you’re not just managing fire.

You’re managing the heat transfer system surrounding your meat.

That’s a big shift in perspective.

You’re not just cooking with heat.

You’re cooking with moving heat.

Smoke Density and Flavor Saturation: More Is Not Better

Let’s bust a myth.

More smoke does not mean more flavor.

Smoke flavor works through surface interaction.

Once the outer layer of meat absorbs available compounds, it reaches a point of diminishing returns.

After that?

Excess smoke builds bitterness, not flavor.

This is where airflow becomes critical.

Steady airflow prevents smoke from accumulating too densely in the chamber.

It keeps smoke fresh.

Clean.

Balanced.

Heavy smoke saturation happens when airflow is weak and smoke lingers.

That lingering smoke deposits thick compounds unevenly.

So if you want layered, nuanced flavor – not an ashtray brisket – you want clean, moving smoke.

Not clouds.

Understanding this reframes how you think about intensity.

Flavor comes from clean combustion, not smoke volume.

Fire Size vs. Airflow Balance: The Big Fire, Small Fire Debate

You’ve probably heard two camps argue:

“Run a small controlled fire.”

“No, run a bigger, cleaner-burning fire.”

Here’s the truth.

A slightly larger fire with strong airflow often burns cleaner than a tiny fire starved of oxygen.

Small fires can smolder.

Smoldering produces dirty smoke.

Larger fires create stronger draft.

Stronger draft improves combustion efficiency.

The key isn’t fire size alone.

It’s the balance between fuel load and oxygen supply.

When airflow matches fuel, combustion stabilizes.

When fuel exceeds airflow, chaos begins.

So don’t be afraid of flame.

Be afraid of suffocation.

That mindset shift changes everything about how you manage your pit – and deepens your understanding of the physics of airflow.

Intake Vents: The Gas Pedal

The intake controls oxygen.

More intake = more oxygen = more combustion.

Less intake = less oxygen = slower burn.

But here’s a mistake I see all the time:

People close intake vents too aggressively to lower temperature.

That chokes combustion.

You don’t lower heat.

You dirty the fire.

Small adjustments. Then wait.

Fire responds slowly.

Respect that.

The Firebox: Where Flavor Is Born

This is ground zero.

A healthy firebox has:

- A strong coal bed

- Flames touching new wood

- Minimal smoldering

If wood sits there smoking without flame, airflow is insufficient.

The Cook Chamber: Flow Over the Meat

Air doesn’t just carry heat.

It carries flavor compounds.

Steady airflow:

- Builds bark evenly

- Prevents stale smoke

- Maintains stable temperatures

Stagnant air creates uneven cooking and muddy flavor.

The Exhaust Stack: Leave It Alone

Here’s my golden rule:

Your exhaust stack should almost always be fully open.

Why?

Because exhaust regulates pressure and maintains draft.

Closing the exhaust traps dirty smoke and reduces airflow velocity.

That’s like covering your mouth and trying to run a marathon.

Let the smoker breathe.

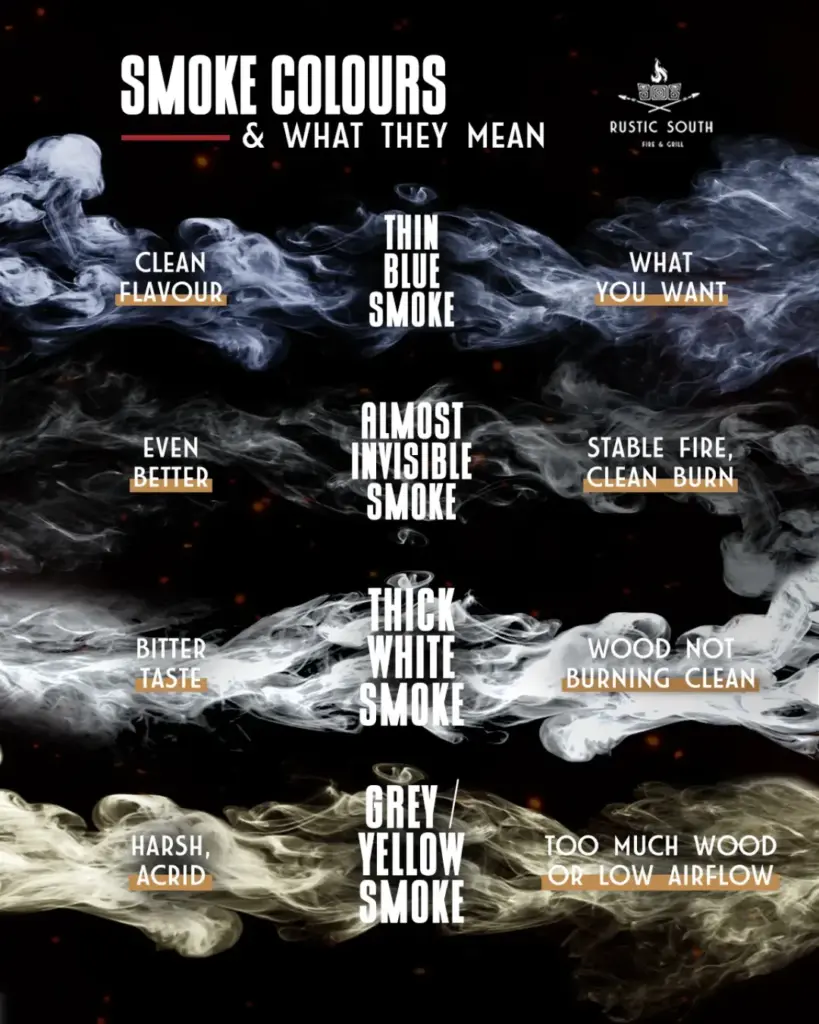

Clean Smoke vs. Dirty Smoke

You’ll hear pitmasters talk about “thin blue smoke.”

It’s almost invisible.

Sometimes you have to squint to see it.

That’s clean smoke.

It smells sweet.

It smells like warm wood.

It smells inviting.

Dirty smoke is obvious.

It’s thick.

It’s white or gray.

It hangs heavy.

It smells sharp.

If smoke burns your nose, imagine what it’s doing to your brisket.

Dirty smoke leaves creosote – a bitter, sticky compound – on the surface of meat.

That bitterness doesn’t cook off.

It sets.

And no sauce can fix it.

The goal isn’t heavy smoke.

It’s efficient combustion driven by proper airflow.

That’s the physics of airflow in action.

How to Control Airflow Like a Pitmaster

This is where theory meets practice.

1. Build a Strong Coal Bed

A coal bed is thermal stability.

Without it, new splits struggle to ignite cleanly.

Let your initial fire burn down into glowing embers before adding wood for long cooks.

2. Preheat Your Splits

Cold wood cools combustion.

Place splits on top of the firebox to warm them.

Warm wood ignites faster.

Faster ignition = cleaner burn.

3. Make Small Vent Adjustments

Think millimeters, not inches.

After adjusting intake, wait 10–15 minutes.

Fire is slow to respond.

4. Don’t Overload Fuel

More wood doesn’t mean more flavor.

It means more volatile gases.

And if airflow can’t keep up, you get dirty smoke.

Add smaller splits more often.

5. Adjust for Weather

Wind can supercharge airflow or suffocate it.

Cold weather increases draft but may require more fuel.

Humidity slightly slows combustion but rarely ruins a cook.

Understanding these patterns is part of mastering the physics of airflow.

Airflow Differences Across Smoker Types

Not all pits breathe the same.

Offset Smokers

These rely heavily on natural draft.

Airflow skill matters most here.

You’re manually balancing oxygen and fuel.

It’s art and physics combined.

Kamado Grills

These are hyper-efficient.

Restricted airflow.

Small vent changes make huge differences.

They hold heat like a vault.

Pellet Smokers

Forced-air systems.

Fans control oxygen.

They automate much of the physics of airflow, but combustion principles remain the same.

Vertical Water Smokers

Heat rises vertically.

Water pans stabilize temperature but slightly alter airflow speed.

Different tools.

Same physics.

Common Airflow Mistakes

I’ve made them all.

Closing the exhaust to lower temp.

Choking intake too much.

Adding three splits at once.

Using damp wood.

Ignoring coal bed development.

Every one of those mistakes disrupts combustion efficiency.

And every one leads back to misunderstanding airflow.

The Physics-Based Clean Smoke Checklist

Before you cook, ask yourself:

- Is the exhaust fully open?

- Do I have a strong coal bed?

- Are my splits preheated?

- Is my smoke thin and light?

- Does the smoke smell pleasant?

If yes, you’re on track.

If not, adjust airflow first – not seasoning, not spritzing, not wrapping.

Fix the fire.

Frequently Asked Questions (FAQs)

Why is my smoker producing thick white smoke?

Thick white smoke usually means incomplete combustion.

That happens when:

- The fire doesn’t have enough oxygen

- The wood is damp or too cold

- You’ve added too much fuel at once

- The coal bed is weak

White smoke often shows up when fresh wood is smoldering instead of flaming.

The fix?

Increase airflow slightly. Make sure your exhaust is fully open. Let the wood ignite fully before closing anything down.

Remember: clean smoke is almost invisible. If you can see heavy clouds rolling out, your fire is struggling.

Should I close the exhaust vent to control temperature?

Almost never.

Closing the exhaust reduces draft, which reduces airflow velocity and combustion efficiency.

That leads to:

- Dirtier smoke

- Creosote buildup

- Bitter flavor

Control temperature with the intake vent, not the exhaust.

The exhaust maintains pressure differential. It keeps the system breathing.

Think of it this way:

- The intake is your gas pedal.

- The exhaust is your lungs.

- Don’t choke your lungs.

Why does my BBQ taste bitter even though the temperature was steady?

Because temperature isn’t the whole story.

You can hold 250°F all day and still produce dirty smoke if combustion isn’t efficient.

Bitterness usually comes from:

- Smoldering wood

- Poor airflow

- Trapped smoke

- Creosote buildup

This is where the physics of airflow really matters. Stable heat doesn’t guarantee clean combustion.

Always judge smoke by smell and appearance – not just by what the thermometer says.

What does “thin blue smoke” actually mean?

It doesn’t always look blue.

It often looks almost invisible – just a faint shimmer leaving the stack.

That’s thin blue smoke.

It means:

- Combustion gases are igniting properly

- Oxygen supply is balanced

- The fire is burning clean

If you have to stare into sunlight to see it, you’re probably in the sweet spot.

If it looks like a steam engine from 1920, something’s off.

How much airflow is too much?

Great question.

Too much airflow can:

- Make your fire burn too hot

- Increase fuel consumption

- Dry the surface of meat too quickly

But here’s the key: it’s rare to have “too much” airflow if your intake is properly sized and your fire is balanced.

Problems usually come from too little airflow, not too much.

The goal isn’t maximum airflow.

It’s balanced airflow matched to fuel load.

Why does my fire die when I close the intake vent slightly?

Because combustion is oxygen-dependent.

Even small intake adjustments can significantly reduce oxygen supply, especially in efficient smokers like kamados.

Fire doesn’t respond instantly.

You may think nothing changed – then 10 minutes later, the flame collapses.

That’s delayed oxygen starvation.

Make small changes. Then wait.

Fire has momentum.

Airflow has inertia.

Respect both.

Does weather really affect airflow that much?

Absolutely.

Cold weather increases draft because the temperature difference between inside and outside air grows.

Wind can:

- Increase draft if it hits the intake

- Reverse draft if it hits the exhaust incorrectly

- Cause unstable temperature swings

Humidity has minor impact compared to wind and temperature.

If your smoker acts “weird” on a windy day, it’s not haunted.

It’s physics.

Why does my smoke look clean at first, then turn dirty after adding wood?

Because fresh wood goes through stages:

- Moisture evaporation

- Pyrolysis

- Flame ignition

During those first stages, you may see temporary white smoke.

That’s normal – briefly.

If it lasts more than a few minutes, airflow or coal bed strength may be insufficient.

Preheating splits and maintaining a strong ember base solves most of this.

Is more smoke flavor always better?

No.

Smoke flavor saturates the surface of meat.

After that, excess smoke builds bitterness, not depth.

Heavy smoke doesn’t mean stronger flavor.

It usually means inefficient combustion.

Clean, steady airflow produces layered, balanced smoke flavor.

That’s the difference between competition-level brisket and backyard ashtray.

What’s the single biggest airflow mistake beginners make?

Choking the fire to control temperature.

When temperature rises, they panic and shut vents aggressively.

That reduces oxygen.

Which reduces combustion efficiency.

Which produces dirty smoke.

Instead:

- Make small intake adjustments

- Keep exhaust open

- Let the system stabilize

The biggest shift you can make as a pitmaster is this:

Stop fighting temperature.

Start managing airflow.

That’s mastering the physics of airflow.

Master the Air, Master the Fire

BBQ isn’t mystical.

It’s not luck.

It’s not secret rub formulas.

It’s combustion science.

It’s draft mechanics.

It’s the physics of airflow applied with patience.

Once you learn to read smoke, feel airflow, and respect oxygen, you stop chasing temperatures.

You start managing systems.

And when that happens, your brisket tastes cleaner.

Your ribs taste deeper.

Your chicken skin turns perfect.

Because clean fire produces clean flavor.

Air feeds the fire.

Fire flavors the meat.

And airflow controls it all.

That’s not just pitmaster talk.

That’s physics.

Featured image credit: @blue_collar_pits_smokers